Handling of automotive components: how to carry it out safely

The importance of safety in handling car components

In the automotive sector it is necessary to ensure that the handling of car components is carried out safely, trying to limit as much as possible damage or risks related to transport. The implementation and use of advanced technological solutions and resistant materials in handling operations of materials and auto components are therefore essential to ensure a safe working environment for operators during the various processes, In addition to protecting the various components.

The optimization of transport and handling of materials can also contribute to improve safety at work, reducing the possibility of accidents or injuries and ensuring greater protection of workers’ safety.

This process involves key equipment such as metal racks, specifically designed to ensure efficiency and productivity in handling, storage and transport of car components.

Metal racks: an effective solution for handling

Metal racks play a fundamental role in the automotive sector to optimize the storage, handling and transport of car components within production facilities. Depending on the type of production, the characteristics of the production lines and the parts to be contained, different types of metal containers can be used, each with specific characteristics and applications, such as:

Metal racks play a fundamental role in the automotive sector to optimize the storage, handling and transport of car components within production facilities. Depending on the type of production, the characteristics of the production lines and the parts to be contained, different types of metal containers can be used, each with specific characteristics and applications, such as:

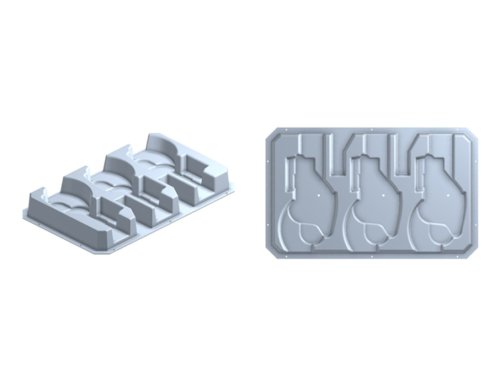

- specific metal racks developed for components, custom-designed to accommodate specific types of auto components, of different shapes and sizes, such as mechanical parts, structural or plastic. They are made of high-strength materials and designed to ensure a long life;

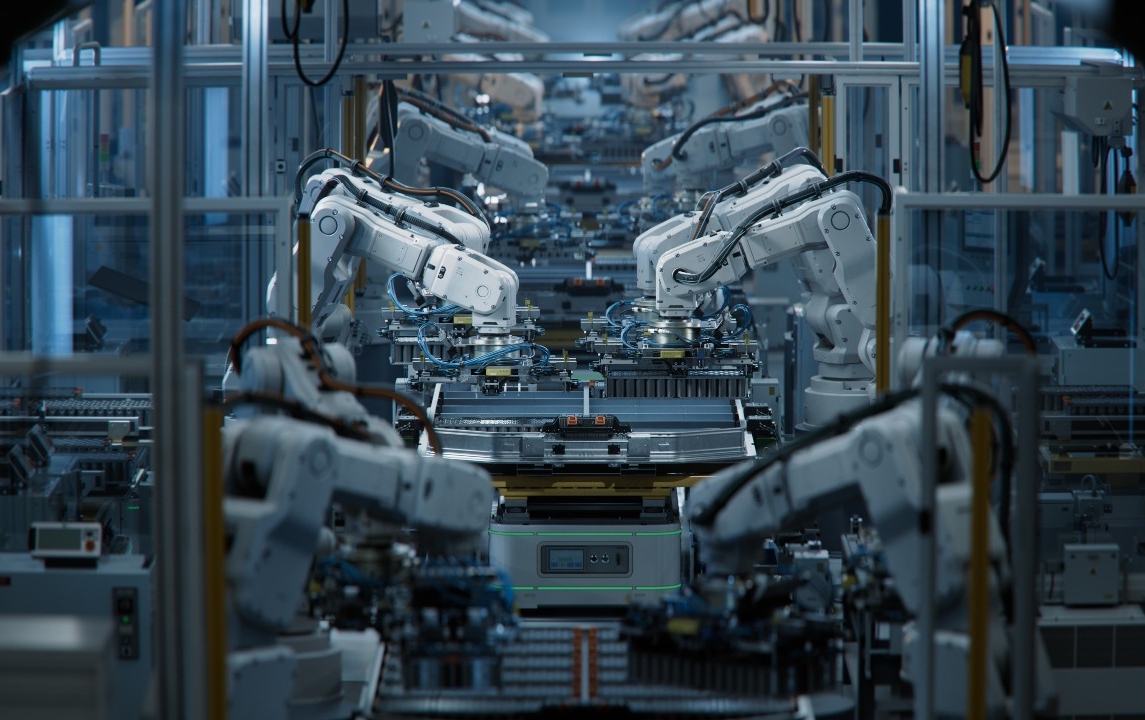

- metal racks with stacker pillars, characterized by the presence of metal pillars, internal supports that allow to accommodate and organize car components inside the rack itself. They are suitable for loading and unloading of parts by robots and, thanks to their special structure, they can be used to support the elements by means of movable flaps which are automatically armed during the loading operations on the workpiece, without the need for an operator. This makes them ideal for preventing possible damage during storage and handling operations, ensuring greater protection and organization of components.

The advantages of automotive metal racks for component transport

Automotive metal racks are widely used for car components transportation and can offer numerous production optimization benefits, including:

- component protection: during handling and/or transport, they protect even the smallest or most delicate components. They are designed to withstand shocks and weather, minimizing damage during transport;

- reduced loading and unloading times: metal containers allow faster loading and unloading of components, simplifying handling operations and saving valuable time during production;

- greater efficiency in logistics and transport: thanks to their specific design, these containers allow easier and faster movement of components, reducing processing times and increasing company productivity;

- storage is easy: this allows maximum use of available space and simplifies handling operations;

- reduction of business costs: thanks to their re-usability, metal containers can be used several times for the transport and storage of car components, thus reducing business costs;

- customization possibilities: the containers can be precisely adapted to the different shapes and sizes of the components, so as to meet the specific production needs of the company.

Ferrero Automotive metal racks: innovative solutions to optimize handling and transport operations

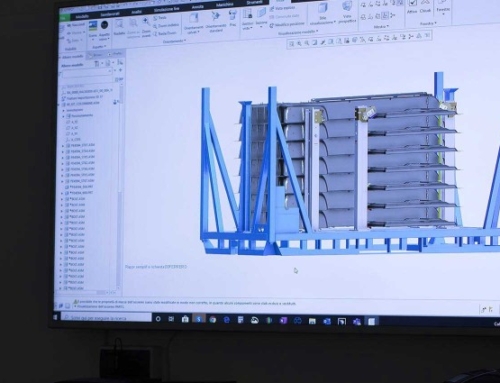

Ferrero Automotive’s metal racks represent innovative and cutting-edge solutions to optimize the handling and transport of car components within production facilities. Designed with advanced technologies and a particular focus on aspects such as strength, efficiency and safety, they are made of high quality materials that guarantee long-term durability and resistance to shocks, deformation and mechanical stress conditions. Thanks to their particular structure and the possibility of being stacked safely, they allow you to make the best use of the available space, reducing space and facilitating logistics operations.

Ferrero Automotive’s metal racks represent innovative and cutting-edge solutions to optimize the handling and transport of car components within production facilities. Designed with advanced technologies and a particular focus on aspects such as strength, efficiency and safety, they are made of high quality materials that guarantee long-term durability and resistance to shocks, deformation and mechanical stress conditions. Thanks to their particular structure and the possibility of being stacked safely, they allow you to make the best use of the available space, reducing space and facilitating logistics operations.

All the containers produced by the company are also designed to fit perfectly to components and details of different shapes and sizes, protecting them from mechanical damage. This translates into a significant reduction in scrap and repair costs, with a positive impact on business productivity and an overall improvement in the efficiency, safety and sustainability of automotive logistics operations.

As far as the safety of workers is concerned, Ferrero Automotive guarantees that its products meet all the safety and compliance regulations of the automotive sector, protecting the safety of those who operate the machines and complying with precise quality standards.

If you are interested in receiving more information about metal racks or would like to request a consultation, contact us!