Custom metal racks: what are the advantages?

Specific metal racks: the importance of a customized design

With the advent of digitalization, the latest automation technologies and new business models, the automotive industry has revolutionized itself to such an extent that it must continuously optimize and revise its production processes. The demand and need to produce an ever-wider variety of car models is growing.

In this context, specific metal racks are an essential tool. Their versatility comes from the ability to be custom designed to fit different shapes and sizes, offering efficient solutions to manage different types of accessories and customized car components.

What are custom metal racks and what do they serve

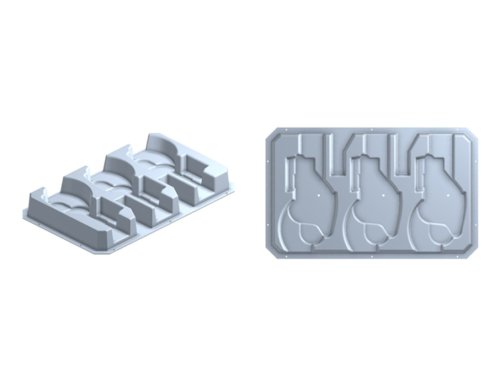

Custom metal racks play a fundamental role in the automotive sector because they allow the optimization of storage, handling and transport of car components within production facilities. Depending on the type of use, the types of components to be accommodated and the specific production requirements, different types of specific metal racks can be used, which differ in characteristics and application possibilities. These include:

- specific metal racks: custom designed to accommodate specific types of automotive components (such as mechanical, structural or plastic parts). Thanks to their versatility, they allow the optimization and acceleration of the different stages of production and logistics;

- metal racks with stacker pillars: characterized by the presence of stacker pillars that allow to organize and support the auto components inside the rack itself, they are designed to facilitate and speed up loading and unloading operations.

To fit components of different shapes and sizes, specific metal racks require precise design and the use of materials that can be easily shaped and modified, while ensuring high strength and durability.

All metal racks offered by Ferrero Automotive are made of certified and high quality materials, designed to best meet the needs of the automotive sector. Among the most used are high-strength steel and stainless steel, which can also be subjected to specific treatments according to the requirements and needs of each customer. High strength steel is distinguished by its strength and durability, and is able to withstand more impact and wear. Stainless steel is known for its high corrosion resistance and ensures that metal racks always remain in perfect working condition.

The advantages of custom metal racks

The use of metal racks in the automotive sector can provide numerous advantages, ranging from component protection to increased logistics efficiency, up to the possibility of customization:

- superior protection: metal racks provide a safe barrier against shocks, vibrations and adverse environmental conditions. Protect components during transport and storage, keeping them in perfect condition;

- logistics efficiency: racks allow faster and easier movement of parts, reducing processing times and optimizing production flows. This results in higher productivity;

- durability and sustainability: the average life of metal racks in the automotive sector is about six to seven years, corresponding to the production life cycle of a car model. The possibility of re-using them and adapting them to new production needs helps to reduce waste and promote more sustainable industrial practices;

- ease of handling and storage of components: metal racks are custom-made and designed to accommodate specific types of components, which can facilitate storage operations and facilitate transport within the plants;

- customisation according to the specific production needs of the company: customized metal racks can be adapted exactly to the needs of the company, ensuring a safe handling of components and efficient handling.

Thanks to these advantages, metal racks are an optimal option for those looking for a durable and versatile solution for the management of automotive components, especially in high-intensity production environments that characterize the automotive sector.

Custom-made metal racks: the customization options offered by Ferrero Automotive

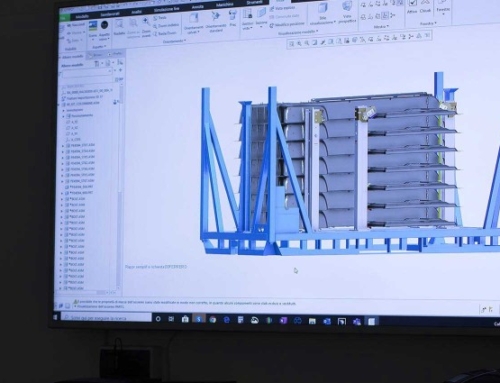

Ferrero Automotive is specialized in the design and manufacture of metal racks for the automotive industry, offering a full range of customization options to meet the specific needs of its customers. We are able to manufacture custom metal racks following every stage of the design, from the initial study phase, starting with the 3D model of the components supplied by the customers, up to the final design and production.

The use of 3D models in the design of automotive metal racks offers many advantages. This technology allows the rack to be visualized in a detailed and realistic way before actual production. In addition, thanks to the use of CAD systems it is possible to customize the design according to specific needs and to perform feasibility analysis and virtual simulations to optimize the maximum number of details to be contained, move or transport inside the racks, guaranteeing at the same time their aesthetic and functional quality.

This type of design allows metal racks to be perfectly adapted to the specific dimensions of the automotive components, thus guaranteeing greater safety during transport.

Another important aspect of customizing automotive metal racks is the choice of type of paint and coating. Painting techniques not only protect the metal from corrosion and wear, but also offer a wide range of colors and finishes. This improves the appearance of specific metal racks, while facilitating their identification and handling.

The ability to design and manufacture metal racks to meet the specific needs of each customer makes Ferrero Automotive an ideal partner for companies that need tailor-made solutions to improve their productivity and protect their components.

If you need more information about custom metal racks offered by Ferrero Automotive or request a quote, contact us.