Guide to the choice of metal racks for the automotive sector

All the useful tips to choose the most suitable automotive racks for each production line

Metal racks play a fundamental role in the automotive sector to optimize the storage, handling and transport of automotive components within production plants. These racks provide an efficient and safe solution to safely protect and handle even the smallest and most delicate parts and components throughout the production chain.

The choice of the most suitable metal racks for each specific product and production line is extremely important in order to optimize and speed up production and all logistics activities. The different car components can in fact require specific storage and transport modes in terms of size and weight. Using unsuitable racks may compromise the integrity of components and cause damage during handling or transportation, resulting in the company wasting time and resources to replace or repair damaged components. In addition, to choose the most suitable automotive racks, it is also important to consider compatibility with automatic handling systems and ease of movement and transport, which can significantly influence the efficiency and productivity within the plants.

Let’s see together what are the different types of metal racks used in the automotive sector and all the features to consider to help you choose the most suitable solutions for the needs of your company.

Types of metal racks for the automotive sector

Different types of metal racks can be used within the production facilities, each with specific characteristics and applications. These include:

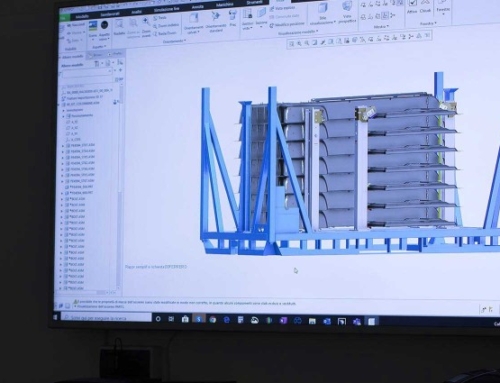

- automatic loading/unloading racks used in robotic lines: these racks are designed to be used in automated production lines, allowing automatic loading and unloading of car components. They are usually equipped with guides and supports to ensure a precise positioning of the materials and are made of resistant materials to withstand the mechanical stresses of robotic machines;

- metal racks with stacker pillars, characterized by the presence of columns or internal supports that allow you to organize and separate car components inside the container itself. Their particular structure helps to prevent damage during storage and handling operations, ensuring greater protection and organization of car parts;

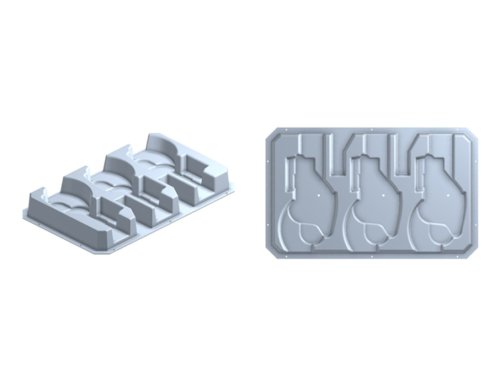

- specific metal racks for components: these racks are custom designed to accommodate specific types of automotive components, of different shapes and sizes, such as mechanical, structural or plastic parts. They can have internal compartments, partitions or dedicated supports for each type of component, optimizing space and facilitating the management and accessibility of materials during the production and assembly phases.

All types of racks allow to speed up and improve the efficiency of storage and handling of car components. The use of metal racks specially designed for automatic loading/unloading in robotic lines ensures an efficient and smooth workflow, offering an optimal organization of the parts, reducing the risk of damage and picking errors, and at the same time increasing the productivity and quality of the production process.

Characteristics to consider when choosing metal racks

When choosing automotive metal racks, it is essential to consider a number of features to ensure that they are suitable for the specific needs and types of application. Among the aspects to be taken into account are:

- dimensions and load capacity: it is important to carefully assess the dimensions and load capacities of racks in relation to the car components to be transported, ensuring that they can safely and efficiently accommodate parts without risk of damage or overload. Also consider the size of racks to ensure they are compatible with the available handling equipment and storage spaces;

- strength and durability of materials: automotive parts racks must be made of robust and resistant materials, able to withstand the mechanical and environmental stresses typical of automotive plants. In addition, they must be specially designed to withstand the weight of components and any impact during transport and storage. Make sure that they are made of high quality steel, which can guarantee high strength and durability;

- compatibility with robotic systems and handling equipment: it is essential to verify that racks are compatible with the automated handling systems and equipment present in the plants, so as to facilitate loading operations, unloading and speeding up the production cycle and logistics processes;

- easy handling and storage of components: it is important to choose custom-made racks, designed to accommodate specific types of components, which can facilitate storage operations and facilitate transport within the plants. Racks should ensure safe and efficient handling of parts, minimizing the risk of damage;

- compliance with safety regulations: it is essential to verify that the racks meet all the safety and conformity regulations of the automotive industry, ensuring the safety of workers and compliance with precise quality standards.

Carefully considering all these aspects in the choice of metal racks will allow you to choose the most suitable solutions for each type of application, ensuring efficient, safe and reliable operations within the automotive plants.

Ferrero Automotive metal racks: advantages and applications

Metal racks proposed by Ferrero Automotive are designed to ensure strength, versatility and efficiency to companies in the automotive sector who want to speed up and optimize production processes and improve their logistics operations. The high quality and strength of materials used in the production of racks ensure reliable protection of components during all stages of the production and logistics chain. These racks are also designed to withstand heavy loads and mechanical and environmental stress, ensuring the safety and integrity of the transported parts. Thanks to their durability, Ferrero Automotive racks represent a long-term investment for companies in the automotive sector, also reducing replacement and maintenance costs.

The particular structure of automotive parts racks is designed to facilitate loading, unloading and handling operations within the plants, improving efficiency and productivity. All products can be manufactured in size and with the specific characteristics required by each customer, to ensure full compatibility with existing automated plants, reduce downtime and optimize workflow. The versatility of Ferrero Automotive containers makes them suitable for a wide range of applications in the automotive sector, from production lines to storage areas, ensuring an effective and organized management of car components.

For more information on metal containers or other products or services offered by Ferrero Automotive, contact us!

Leave A Comment