Car battery containers: applications and benefits

The importance of containers for the transport and storage of car batteries

The evolution of electric mobility, with the increasing use of high-capacity lithium batteries, has imposed new standards for safety, efficiency and sustainability in the automotive sector. Batteries, both new and used, are components that must be handled with care: they are heavy, potentially dangerous if damaged or exposed to extreme environmental conditions, and subject to strict regulations on handling and disposal. For this reason, companies in the automotive sector – from vehicle manufacturers to first-tier suppliers and recycling centres – must have certified containers, specially designed to ensure safe transport and stable storage of batteries, avoiding risks related to leakage or shock.

In addition to the protective function, car battery containers must meet practical requirements such as optimization of storage space and transport equipment, ease of handling and the possibility of being reused in a circular economy. The adoption of specific solutions for battery logistics can therefore contribute not only to operational safety and compliance with international regulations, but also to the overall efficiency of production and distribution processes in the automotive sector.

Let’s see in more detail the different applications of containers for car batteries, their advantages and the innovative solutions proposed by Ferrero Automotive.

What are car battery containers and what are they for

Car battery containers are specially designed structures to ensure the safe transport, handling and storage of batteries for vehicles, whether electric, hybrid or conventional. As we have seen, these containers not only protect the batteries from physical damage, but also help to optimize logistics processes within the automotive industry.

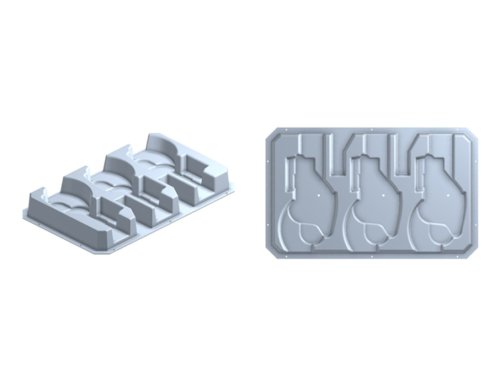

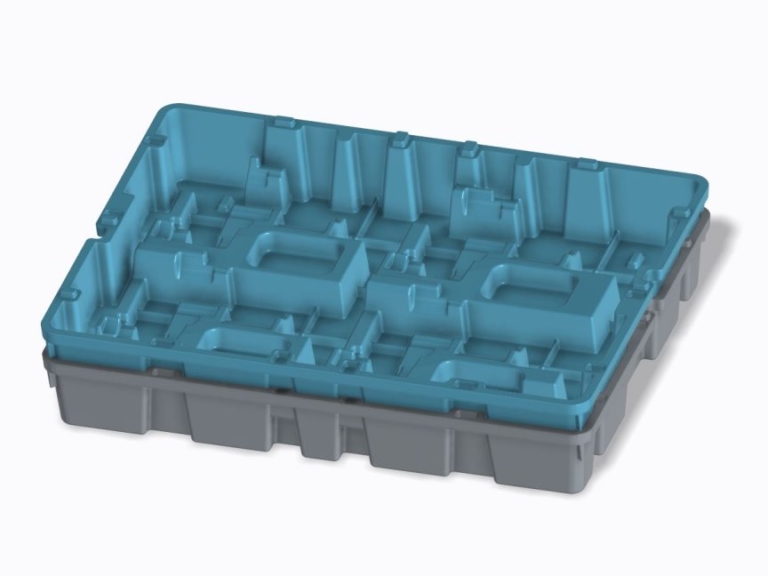

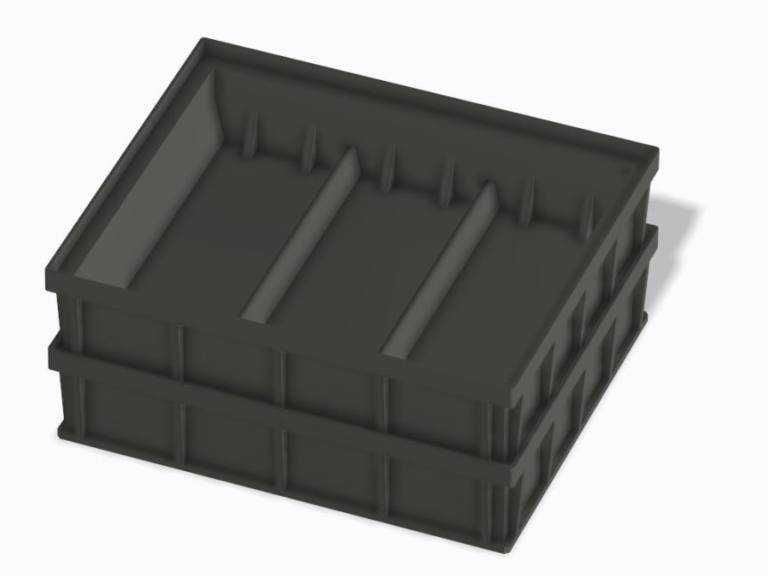

Depending on operational requirements, the containers can be made of plastic or metal materials, each with specific characteristics that meet different industrial requirements. Plastic containers are lighter and easier to stack, ideal for optimised storage, while metal containers offer greater strength and are therefore better suited for more demanding transport conditions.

The main characteristics and properties of car battery storage containers include:

- advanced protection: they are designed to absorb shock and vibration, thus minimizing the risk of damage to batteries during transport and storage;

- stackability and space optimization: the containers are designed to be easily and safely stacked, even when fully loaded. This feature is key to reducing storage space and maximizing usable space in transport vehicles;

- ease of handling: they can be equipped with integrated solutions to simplify safe movement using forklifts, pallet trucks or automated systems. This results in greater operational efficiency and reduced transportation costs.

- regulatory compliance: they are designed in full compliance with the safety and quality standards required by the automotive industry.

Because of these features, automotive battery containers are an indispensable solution for companies in the industry, ensuring efficient and safe management of batteries at every stage of their life cycle.

Applications of car batteries storage containers in the automotive industry

Car battery storage containers can find use at various stages of production and logistics management within automotive industry facilities. One of the main areas of use is during the assembly and production phase, where the containers help maintain an orderly workflow, ensuring that the batteries arrive at the assembly lines in perfect condition.

In addition, in intermediate or long-term storage warehouses, these containers enable rational and efficient storage of batteries, optimizing available space and ensuring safer and more effective organization.

They also find applications for transportation between production facilities, which often involves travel over long distances. Car battery containers enable this activity while minimizing the risk of accidents and damage to components, ensuring compliance with regulations for the handling of sensitive materials.

Finally, at the disposal and recycling stage, they can facilitate the transport of spent batteries to specialized treatment centers, reducing the risk of leakage of harmful substances and contributing to environmental sustainability.

The advantages of car batteries containers

The use of battery containers can bring several benefits to automotive manufacturers and industries by improving safety, efficiency, and operating costs. A first significant benefit is the safeguarding of people and facilities, thanks to the structure designed to prevent accidents, reduce the risk of damage, and protect operators when handling batteries.

From an operational perspective, battery containers also help improve logistical efficiency, reducing downtime and increasing overall productivity. The use of custom-made, easy-to-handle containers enables optimization of internal processes, speeding up loading and unloading operations. In addition, their high strength and durability contribute to a significant reduction in operating costs by reducing the need for container replacement.

An additional advantage is the possibility of customization, which allows the containers to be adapted to the specific needs of each company. Tailor-made solutions – such as those proposed by Ferrero Automotive – can further improve logistics performance by ensuring perfect battery storage and more efficient space management.

Ferrero Automotive’s car battery storage containers

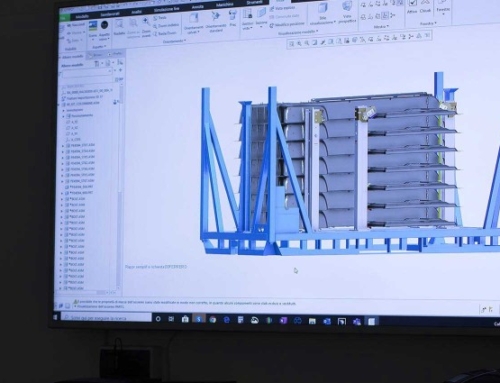

Ferrero Automotive specializes in the production of custom-made car battery containers designed to offer efficient, safe and fully customizable solutions. The company constantly strives to innovate and research cutting-edge materials and designs to meet the increasingly specific needs of automotive companies.

Plastic racks are the ideal solution for containing and moving these components in an orderly and safe manner, ensuring maximum structural strength. In fact, they are designed to provide protection from external agents and any mechanical stresses during handling. Metal racks with stacker pillars, on the other hand, can be used in automated facilities to facilitate the loading and unloading of batteries, improving logistics efficiency and reducing handling time. Their solid construction makes them particularly suitable for intensive use in manufacturing and transportation environments. They are designed to fit perfectly with different types of batteries and components, minimizing the risk of damage and optimizing storage and transportation space.

Relying on Ferrero Automotive means choosing an experienced and reliable partner with a long experience in the automotive industry, capable of ensuring high quality standards, cutting-edge production technologies and a strong focus on environmental sustainability.

If you need more information, please contact us!