Automotive racks for automatic lines

Precision instruments at the service of industrial robotics

The automotive industry is constantly driven by the search for greater efficiency and high quality standards. Fully automated production lines and robotic systems have undoubtedly taken on a central role, especially in recent years. However, their effectiveness does not lie solely in the speed of the mechanical arms, but is closely linked to the quality and precision of the tools that support production and internal logistics, such as automotive racks for automatic lines specifically designed to allow the loading and unloading of components by robot.

The role of automotive racks in robotic handling

When designing a robotic line, the concept of tolerance takes on significant importance. A robot that must pick up a component is programmed to act in a well-defined spatial point and, for this very reason, racks for car components intended to interact with robotics must guarantee dimensional and positioning precision that goes beyond simple functionality of storage. Any minimal deviation in the workpiece housing, perhaps caused by a deformed, unstable or simply unsuitable container, can trigger a vision error, incorrect positioning of the gripper or, in the worst case scenario, a blockage of the production line, with high costs and delays in delivery.

When designing a robotic line, the concept of tolerance takes on significant importance. A robot that must pick up a component is programmed to act in a well-defined spatial point and, for this very reason, racks for car components intended to interact with robotics must guarantee dimensional and positioning precision that goes beyond simple functionality of storage. Any minimal deviation in the workpiece housing, perhaps caused by a deformed, unstable or simply unsuitable container, can trigger a vision error, incorrect positioning of the gripper or, in the worst case scenario, a blockage of the production line, with high costs and delays in delivery.

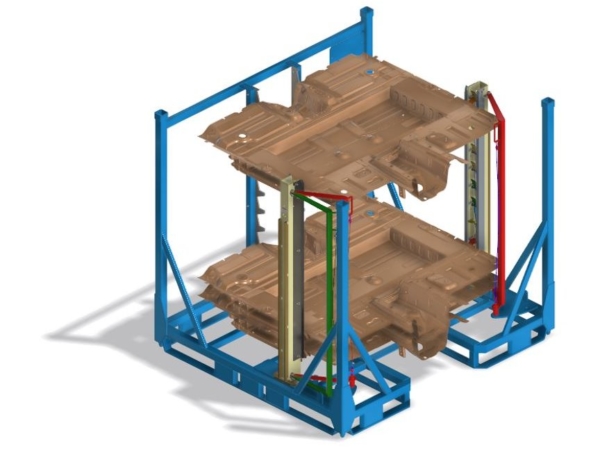

The production of metal carpentry intended for the automotive sector of Ferrero Industrial responds precisely to this need: we create robust containers, designed to resist the stresses of industrial handling and, at the same time, dimensionally stable, to keep the housing geometry unchanged. Our automotive racks for automatic lines are support systems engineered and made with advanced technologies, which can be equipped with specific columns to facilitate the storage and movement of components, as well as internal positioning systems that immobilize the pieces in an exact point.

Thanks to their particular characteristics, robot vision systems or sensors can identify and pick up components with maximum speed and accuracy, integrating perfectly with operational cycles. The investment in high-precision automotive racks is directly proportional to the reliability and overall performance of the automatic line.

Structural integration and operational flexibility

The effectiveness of an automated system depends on its ability to handle a variety of components without significant disruption, and automotive manufacturers need solutions that can evolve with vehicle models and line configurations. For this reason, the best racks for transport and handling are those that offer a balance between customization and modularity.

In addition to automotive containers for automatic lines, our range includes different types of supports, ranging from metallic platforms optimized for forklifts and AGV (Automated Guided Vehicle) systems, up to plastic containers, ideal for storage and transport of smaller and more delicate components. The main feature of automotive racks is the ability to be recognized and managed by automation systems. A metal container designed for automatic lines must have clear and repeatable attachment points and geometric references, which act as a “language” spoken by the container with the robotic system.

Furthermore, the design must consider not only the picking phase, but the entire life cycle within the factory. This includes:

- stackability, to optimize warehouse spaces and empty transport (reverse logistics);

- wear resistance, as containers must withstand thousands of loading, unloading and robotic interaction cycles without undergoing deformations that compromise precision;

- integration with systems, i.e. the ability to adapt containers for positioning on conveyor belts or roller systems, always maintaining maximum load stability.

This operational flexibility, guaranteed by a design attentive to the dynamics of industry 4.0, is what allows car manufacturers to operate with just-in-time logic and minimize the online warehouse buffer.

Plastic racks: when lightness meets robustness

For smaller components, semi-assembled components or those requiring surface protection, the use of plastic racks for transport and storage can be used. Also in this case, integration with automatic lines is fundamental: these containers, in fact, must be made with high-resistance materials (such as polypropylene or HDPE) to prevent the weight of the contents or the mechanical stresses from altering their shape, guaranteeing a perfect correspondence with the housing shapes and locking systems.

Their usefulness extends to the intermediate storage and power supply of manual or semi-automatic workstations, offering a practical and lightweight solution that optimizes the use of vertical and horizontal space.

Ferrero Automotive: excellence in the production of containers for robotic lines

Ferrero Automotive is a point of reference for all those companies that intend to achieve the maximum level of efficiency in their automatic production lines. Our experience in the field of specialized metal carpentry and in the production of metal racks allows us to create reliable and technologically advanced solutions, designed to allow companies to increase the speed and efficiency of handling and storage operations.

We offer automotive racks designed for tight tolerances and maximum stability, ideal for robotic integration; robust, tailor-made handling platforms and high-quality plastic racks for optimized storage.

Contact us for more information on our products or to request personalized advice and find out how we can make your production smoother and more efficient.