The importance of 3D design in the automotive sector

From the draft to the digital model: all the advantages of 3D design in the production of metal racks for the automotive sector

In the automotive sector, precision and speed in the production of metal racks represent crucial factors for competitiveness. The introduction of 3D design has profoundly transformed automotive carpentry, allowing production processes to be optimized and margins of error to be significantly reduced. This technology allows you to create extremely detailed digital models, capable of accurately simulating not only the geometries, but also the dynamic behavior of materials under stress, structural stresses in real conditions and interactions between the different parts. This is crucial in the automotive industry, where maximum accuracy is required and tolerances are minimal.

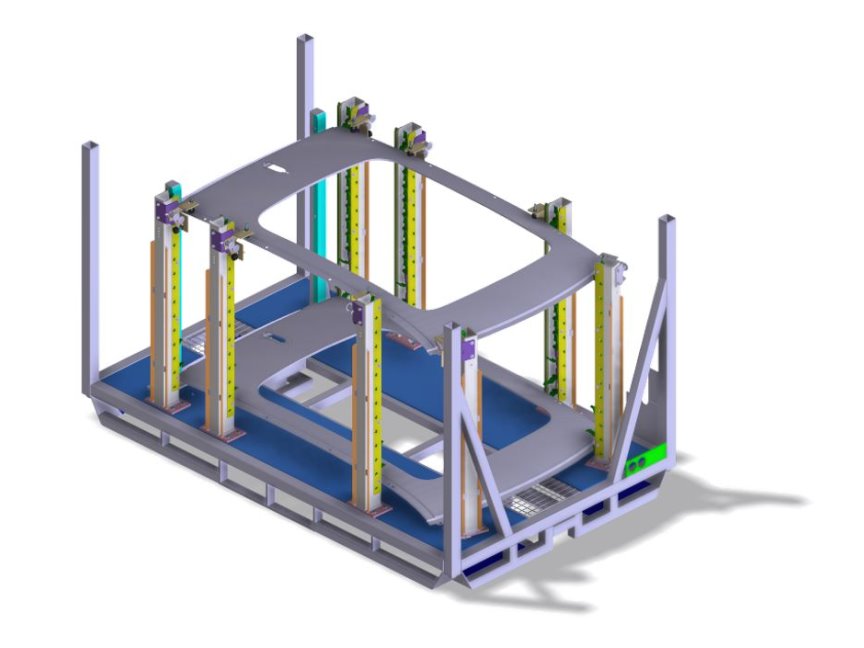

Using 3D for the production of metal racks for the automotive sector means being able to develop virtual prototypes, test different configurations, reduce development times and increase the reliability of the final product. Not only that: thanks to advanced software it is possible to integrate automated production logic (such as CNC bending or robotic welding) already in the design phase, further improving times and reducing costs.

Ferrero Automotive, a company specialized in the creation of specific metal racks for the automotive sector, uses this advanced technology to provide highly precise, functional and customized solutions.

Let’s see in more detail how 3D design works and what advantages it can ensure in the production of metal containers.

How 3D design works

3D design involves the creation of detailed three-dimensional digital models of the racks to be produced. This is a highly structured process, comprising several stages, all of which are closely interlinked and oriented towards the efficiency, precision and quality of the final result. We start from the definition of the technical and functional specifications of the rack to be created. Starting from these specifications, designers use specific advanced three-dimensional modeling software to create a detailed virtual model.

Each element is designed considering the tolerances, the type of material used (steel, aluminum or special alloys), the expected production process and the assembly method. During modeling, structural simulations are performed to evaluate behavior under dynamic loads, impacts or vibrations. This allows you to optimize the racks even before physically producing a prototype, significantly reducing costs and times.

Once the 3D model has been validated, we proceed with the creation of the construction 2D tables, which will be used to create the prototypes. Finally, the model is tested and validated involving designers, production engineers, quality and suppliers. This phase is fundamental to guarantee the quality and safety of the finished product. Only after this phase does we move on to physical prototyping or directly to series production.

The advantages of 3D design in metal carpentry

The 3D design ensures various advantages in the production of automotive carpentry, and in particular specific metal racks, allowing us to improve product quality, reduce waste and speed up delivery times. Among the main benefits that 3D design offers we find:

- absolute precision in construction details: each element or rack can be designed and placed with millimetric precision. This allows you to eliminate any manufacturing errors and ensures that the finished product perfectly meets the required specifications, avoiding subsequent modifications and expensive rework.

- Customer-tailored customization: the 3D model can be easily modified to suit each customer’s needs: size, shape, scope, handling type, stackability, accessories, and more. Just a few clicks are enough to create container variants without having to redesign from scratch, making the process flexible and scalable.

- Simulation of loads and resistances: through integrated software, it is possible to virtually simulate the behavior of the container under stress, such as the weight of mechanical racks, the pressure during stacking or vibrations during transport. This allows you to validate the project before even building a physical prototype, with a significant saving of time.

- Optimization of the use of materials: 3D design allows you to accurately calculate the necessary material, avoiding waste. Furthermore, it allows you to identify areas of the container that can be lightened or simplified without compromising resistance, reducing production costs and facilitating handling.

- Integration with automated manufacturing: 3D models can be exported in formats compatible with CNC machines, lasers, automatic bending machines and welding robots. This allows for faster, more precise and standardized production, increasing the overall efficiency of the production phase.

- Reduction of design and delivery times: with three-dimensional design, once a basic model has been created, it is possible to quickly create dozens of different versions with minimal changes. This allows the entire process to be accelerated, from the actual design phase to the final delivery.

- Better quality control and traceability: each rack can be coded, controlled and monitored digitally, simplifying inspection, quality control and maintenance activities. 3D models can also be archived and updated over time, creating a digital database that is always accessible.

How Ferrero Automotive designs specific metal racks

Ferrero Automotive stands out in the automotive sector for the production of metal racks capable of satisfying the specific needs of each customer. In particular:

Ferrero Automotive stands out in the automotive sector for the production of metal racks capable of satisfying the specific needs of each customer. In particular:

- specific metal racks, tailor-made to fit perfectly into customers’ individual automotive components;

- metal racks with stacker pillars: ideal for facilitating robotic loading and unloading operations, improving robustness, practicality and production speed. These models are widely used in automated lines, where they guarantee maximum efficiency and safety.

The company makes the most of the design through 3D models and advanced CAD software, thus ensuring precision, efficiency and quality at every stage of implementation. The use of 3D models offers significant benefits, allowing a precise and realistic representation of racks even before production. Thanks to CAD systems it is possible to completely customize the design according to the customer’s needs, carry out detailed feasibility analyses and virtual simulations to maximize the quantity of components that the rack can accommodate, move and transport, while simultaneously ensuring aesthetic quality and functionality.

Once the design phase has been completed and the 2D tables have been obtained, the prototypes necessary to concretely validate the technical solutions adopted are created. After their approval, we proceed with actual production, moving from the pre-series to series production, specifically oriented towards the safe and efficient transport of automotive components.

This method ensures perfect dimensional correspondence to the transported components and optimal protection during handling. Ferrero Automotive’s unique ability to develop tailor-made solutions makes the company the ideal partner for all businesses that want to increase productivity and ensure maximum protection of their components.

For further information or to request personalized advice, do not hesitate to contact us. Our team is available to help you identify the solution that best suits your business needs.