Vehicle roof racks

Metal racks for car roofs: robustness, safety and design for every load need

The roof of a car is among the most complex bodywork components to manage in the internal and external logistics of the automotive supply chain. Whether metal roofs, carbon fiber roofs or, increasingly, panoramic glass roofs, their handling and storage must deal with the delicacy of the components, dimensions and weight; this is because, a roof damaged, even minimally, due to incorrect compression or a collision during transport, it results in a high waste cost for the vehicle manufacturer.

Consequently, vehicle roof racks must be designed not as simple supports, but as active protective devices, which integrate the excellence of metal carpentry with advanced ergonomic design.

Car roof racks that ensure maximum resistance and protection

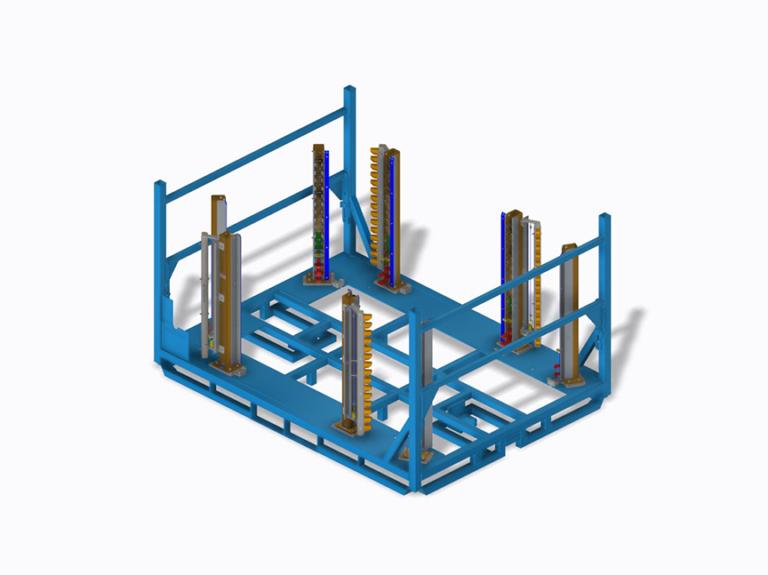

Car roof racks should be designed to support a wide, thin panel without, however, putting any pressure on the most delicate areas. Correct design therefore involves the creation of high-resistance structures, capable of supporting the weight of the component only through predefined contact points.

These racks are made to ensure that the roof remains perfectly stable and firm during all handling and transport phases. The contact points with the roof are always covered with high quality materials, which prevent scratches, micro-abrasions and slipping. For panoramic glass roofs, then, vertical stability is fundamental; therefore, the metal rack must offer a lock that allows for a secure inclination or positioning, often vertically or semi-vertically, to minimize bulk while maintaining maximum protection from bending. Furthermore, the robustness and precision of the housings are essential to resist vibrations during transport, eliminating stresses that could cause harmful micro-movements.

Ferrero Automotive metal racks with stacker pillars are equipped with specific load-bearing structures designed to guarantee maximum stability and stacking capacity. The stackability of vehicle roof racks is of extreme importance for optimizing storage spaces and reducing the number of trips needed for just-in-time supply.

Logistics integration: from the warehouse to the assembly line

An effective containment system must integrate with the customer’s existing logistics infrastructure. This is why our roof racks are designed to guarantee not only maximum protection, but also ease of handling. Handling platforms and structural bases must be compatible with forklifts, pallet trucks and, in many cases, with AGV (Automated Guided Vehicle) systems for automatic line feeding.

A key aspect for bulky body parts is reducing risks for operators. The ergonomic design of the containers, as well as the possibility of accessing the piece without excessive effort, are elements that improve workplace safety and operating speed. Furthermore, the design must facilitate visual inspection of the component without the need to completely extract it. This seemingly minor detail is important to ensure rapid quality controls.

Choose Ferrero Automotive for the transport and movement of car roofs

Ferrero Automotive specializes in the design and manufacturing of specific metal racks for car roofs and the most sensitive bodywork components. Our experience in metal carpentry allows us to provide you with engineered solutions made with cutting-edge production technologies, guaranteeing maximum protection and logistical efficiency.

By choosing our metal containers, therefore, you can achieve a very high structural protection against impacts and static loads (essential for glass and metal roofs), space optimization thanks to the structures with columns for safe stacking and superior durability that the robustness of our carpentry ensures for a long life cycle to the support, reducing replacement costs.

If your priority is to eliminate the risk of damage and optimize the handling of bulky and delicate body panels, contact us for advice and discover our solutions!