Automation in automotive industry: latest technologies and innovations

Advanced industrial automation solutions to improve efficiency, safety and sustainability in automotive manufacturing

The automotive industry is constantly evolving, driven by a relentless drive for efficiency, safety and sustainability. In this scenario, industrial automation is a key factor capable of revolutionizing business processes and shaping the future of production processes and car mobility. Today, car manufacturers are increasingly investing in advanced technologies and digital tools to improve quality, reduce costs and implement production.

Let’s see the latest technologies and innovations that are affecting the industry.

What is automation in the automotive industry

Industrial automation refers to the use of technological systems to control and monitor industrial production processes, minimizing human intervention with machines, robots and automated and digital systems.

Industrial automation refers to the use of technological systems to control and monitor industrial production processes, minimizing human intervention with machines, robots and automated and digital systems.

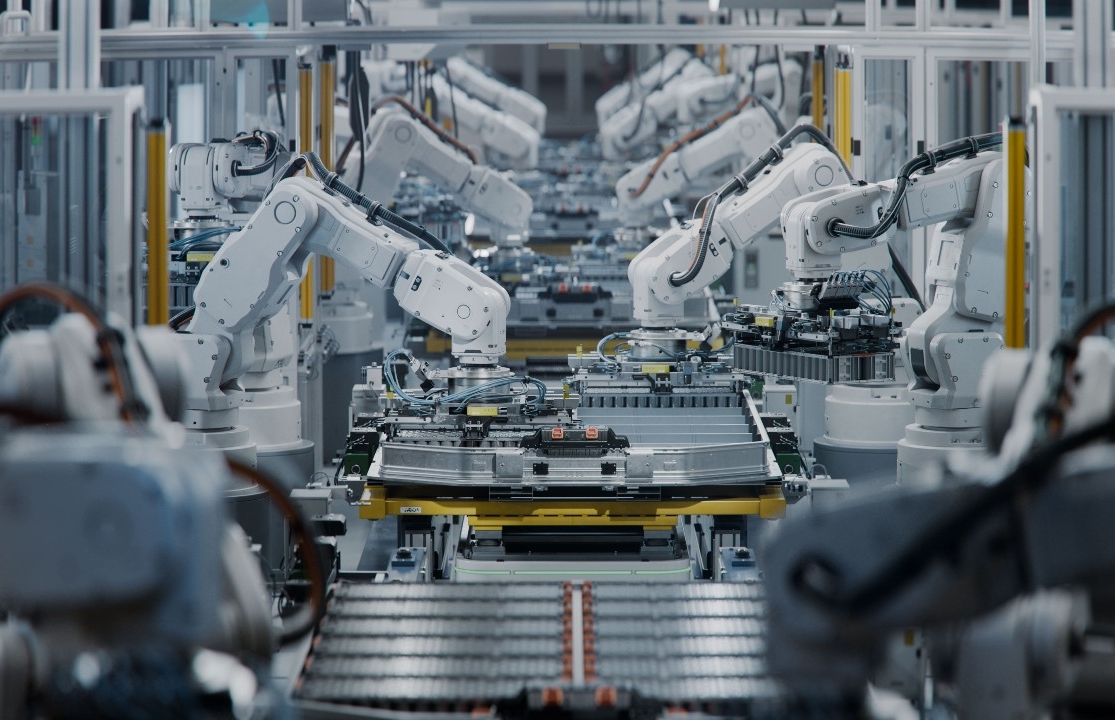

In the automotive industry these processes are key to meeting the growing demand for vehicles with ever higher safety and performance standards. Some of the key areas where automation is used in the automotive sector are:

- assembly and welding: industrial robots are capable of performing a variety of operations, including welding, assembly and component handling, offering precision, speed and repeatability;

- quality control: sensors and artificial vision technologies are used to detect defects in components and finished vehicles, improving the overall product quality;

- internal logistics: automated warehouses, automatic in-house handling systems and self-driving vehicles are all solutions that optimize logistics.

The integration of these procedures in automotive is so deep that today it is difficult to imagine a production plant without the use of advanced technologies.

The advantages of automotive industrial automation

Automotive industrial automation offers companies new production opportunities and contributes to the creation of safer and more efficient components and vehicles. By using advanced technologies such as robotics, artificial intelligence, and IoT (Internet of Things), automotive companies can improve production efficiency, reduce costs and increase product quality. Among the main advantages of industrial automation in the automotive sector there are definitely:

- increased productivity: automation enables 24/7 operations without interruption, significantly increasing the production capacity of assembly lines. Robotized machines, in fact, can perform repetitive tasks quickly and precisely, allowing to reach high production volumes in reduced time;

- quality improvement: using automated systems companies can guarantee a constant quality of finished products. Robots and advanced sensors perform real-time quality checks, detecting defects or inconsistencies in the production process and acting promptly to correct them. This reduces waste and ensures that each vehicle meets the required quality standards;

- lower operating costs: although the implementation of automation requires a high initial investment, long-term operating costs are significantly reduced. Automation reduces labor requirements, errors and the resulting waste of materials. In addition, an optimized control of resources allows to minimize the energy consumption;

- improved safety: automation enables safe operations involving risks to workers, such as handling heavy loads or exposure to harmful substances. Robots and automated machines perform these tasks by reducing the risk of accidents and improving overall safety in production facilities;

- flexibility and customization: automated production lines, supported by advanced control software, allow processes to be quickly adapted to new production requirements, such as the manufacture of custom components. The flexibility of automated machines allows a smooth transition between different configurations, making it possible to respond to market demands quickly and dynamically;

- reduced production time: thanks to automation, cycle times for each production step are greatly reduced, allowing the overall time to bring a new vehicle from design to large-scale production. This advantage translates into increased competitiveness, as companies can bring new models to market in a shorter time.

These benefits make industrial automation an indispensable tool for car manufacturers, who are able to adapt quickly to new market challenges.

The latest technologies and innovations in automotive industrial automation

The combination of industrial automation with technological innovation resulting from the advent of Industry 4.0 is creating new production standards. Interconnected systems, big data analysis and the increasing evolution of digitalization allow the creation of intelligent production lines, where machines communicate with each other in real time.

The main innovations in production processes include:

- collaborative robots (Cobots): these are robots designed to work side by side with human operators. Compared to traditional industrial robots, Cobots are more flexible, easy to program and can be quickly redirected to new tasks, offering greater adaptability in production;

- 3D printing: revolutionizing the way automotive components are produced, allowing for the production of customized parts in a shorter time and with less material waste;

- augmented reality (AR): this type of technology is becoming essential for operator training, machine maintenance and quality control. Operators can use AR visors to view assembly instructions or diagnose mechanical problems in real time;

- artificial Intelligence (AI): is increasingly being used to optimize production processes. Machine learning algorithms analyze real-time data to improve machine performance, predict failures and optimize the supply chain;

- Internet of Things (IoT): connecting machines, sensors and devices, allowing real-time data collection and analysis, improving efficiency and predictive maintenance.

The importance of metal racks in automotive automation

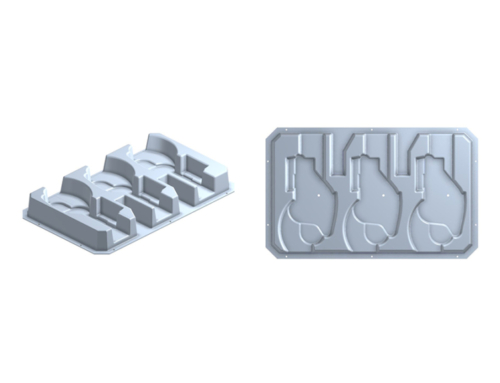

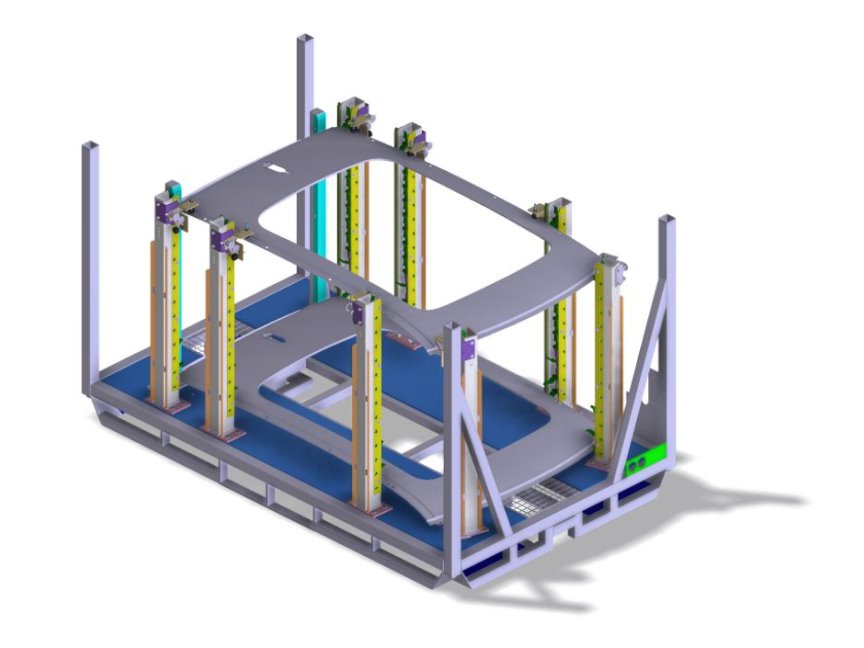

In the context of continuous innovation in industrial automation, Ferrero Automotive produces specific metal racks and metal racks with stacker pillars for handling and storage of car components, specifically designed to integrate with the automotive industry’s robotised lines. Racks are made through careful design, starting from the initial study to final production.

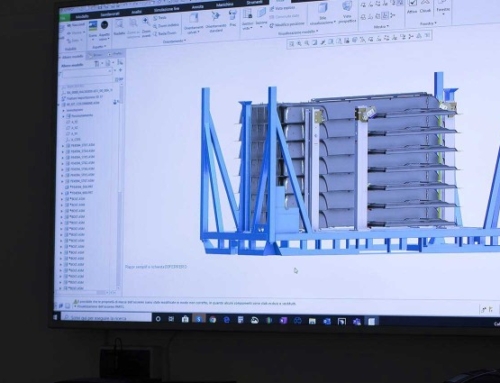

From the 3D models of the components supplied by the customer, the use of CAD software allows the design to be adapted to specific requirements. This allows you to perform feasibility analyses and virtual simulations to optimize the amount of items to be inserted, moved or transported within containers.

The company pays attention to every detail, ensuring that each container is practical and efficient. To ensure the highest precision when handling car components on robot lines, each container is measured with 7-axis 3D boom measuring machines.

Metal racks with stacker pillars, in particular, are designed for loading and unloading of workpieces by robots, thus eliminating the need for manual intervention. They operate on a system of movable tilters, which are supports designed to support and stabilize components during handling operations.

If you are interested in knowing more about how our metal racks work and are made, contact us!