Stacker pillars for automotive racks: what are they for?

Everything you need to know about automatic stacker pillars for automotive racks and their advantages

The automotive sector is constantly evolving and, with it, also the technologies that support the industry. Stacker pillars for automotive racks represent an innovative and highly efficient solution for the management and handling of components within production lines.

These equipment, specifically designed to be installed on special metal racks, play a fundamental role in the process of loading and unloading the pieces, operation that in the automated lines takes place through advanced robots.

The adoption of these technologies can lead to significant improvements in efficiency, safety and overall productivity.

Let’s see more specifically what stacker pillars for automotive racks are, how they work and what benefits they can offer to companies in the sector.

What are automatic stacker pillars for automotive racks?

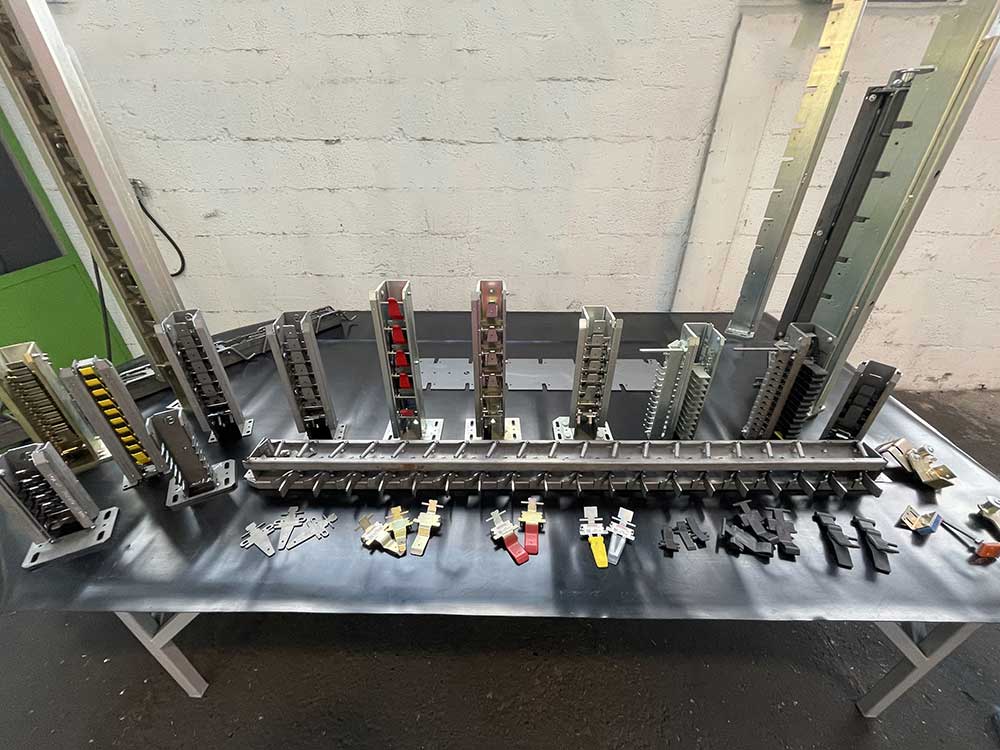

Stacker pillars are mechanical devices installed on specific metal racks designed to facilitate the storage or loading/unloading of car parts and components by robots within the production lines. A distinctive feature of these columns is the presence of movable flaps within their structure. These supports, essential for the correct positioning and safety of the components during transport, are designed to arm and position automatically during loading and unloading, eliminating the need for human supervision and significantly reducing the risk of errors or accidents.

Each column consists of a chamber that houses the flaps and all the necessary mechanisms for the automatic handling of the elements. This system not only ensures a smooth and safe management of the components, but also contributes to improving the overall efficiency of the production process. The integration of these pillars with robotic systems allows perfect synchronization with the rest of the production line, facilitating a continuous workflow and minimizing downtime.

In addition, the design and construction of stacker pillars takes into account the specific needs of the automotive industry, where precision, speed and safety are crucial aspects. The robustness of the materials used, combined with the sophisticated engineering of the internal mechanisms, makes these pillars indispensable tools for companies that aim for excellence in automotive production, while ensuring a high level of reliability and durability.

Advantages of using metal stacker pillars for automatic lines

Metal stacker pillars for automatic lines can offer many advantages to companies in the sector, helping to speed up handling operations and thus increase overall productivity. Among the main advantages of these equipment there are definitely:

- increased efficiency: automatic stacker pillars allow to automate the process of loading and unloading racks, reducing to a minimum the time and effort required for these operations. This leads to an increase in overall production efficiency and a reduction in machine downtime;

- improved safety: pillars reduce the risk of accidents and injuries when lifting and handling workpieces. These devices are designed to ensure safe and controlled lifting of components and car parts of different sizes, minimizing the risk of damage to the items to be handled and the people involved in the process;

- cost reduction: automatic stacker pillars reduce the operating costs associated with the loading and unloading of racks. These devices allow to automate operations that would otherwise require manual intervention by operators, thus reducing labor costs and increasing overall productivity;

- greater precision in operations: they allow workpieces to be positioned with millimeter accuracy within the production line or in loading and unloading processes. This ensures precise alignment of racks with the machines or tools involved in the process, improving the quality and overall efficiency of operations.

Metal racks with stacker pillars by Ferrero Automotive: the ideal solution to optimize production

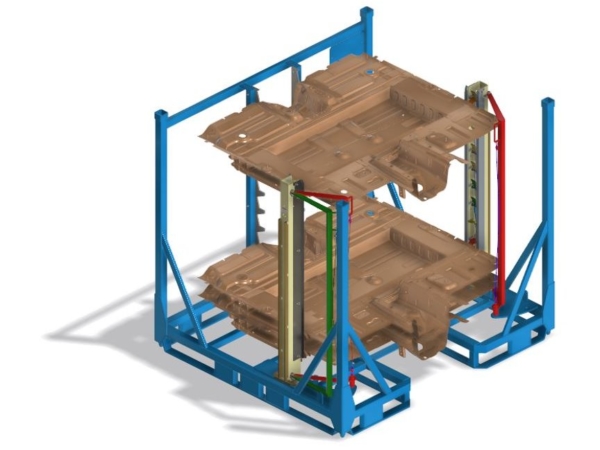

Ferrero Automotive specializes in the design and production of automotive racks with stacker pillars designed to facilitate the handling and storage of car components within automated lines. Racks can be made with specific internal dimensions and configurations, according to the needs of each customer and production line and are designed with particular attention to the safety aspect, to ensure maximum protection of the components during loading and unloading.

The robust construction of racks, combined with the effectiveness of the internal columns, ensures that automotive components are transported in optimal conditions, reducing the risk of damage. This safety is critical to ensuring components arrive at their destination intact and ready for use, which is particularly important in an industry where precision and reliability are essential.

Ferrero Automotive has always been committed to the research and development of cutting-edge solutions in the field of metal racks and is able to follow customers at every stage of the project development: from the initial study phase to the 3D design of racks up to the realization of the prototypes and the 3D measurement to ensure the precise respect of the tolerances that allow the robots the handling of the components.

The continuous push for innovation is further confirmed by the fact that all prototypes and productions related to metal racks with stacker pillars are patented worldwide. This testifies not only the uniqueness and avant-garde of the solutions proposed by Ferrero Automotive, but also underlines the commitment to provide high quality products, which meet the specific needs of the automotive sector.

For more information on automotive racks with stacker pillars or other products or services offered by Ferrero Automotive, contact us!